Our technology research and development center is not merely a laboratory; it is a powerful ecosystem that integrates insight, creation, verification and guarantee. It is the source of confidence for us to provide customers with safe, effective, enjoyable and market-competitive products, and it is also the core driving force that propels the entire industry forward.

All research and development activities begin with a profound understanding of consumer needs. We study market trends, analyze user pain points, and ensure that our innovations are exactly what the market truly requires.

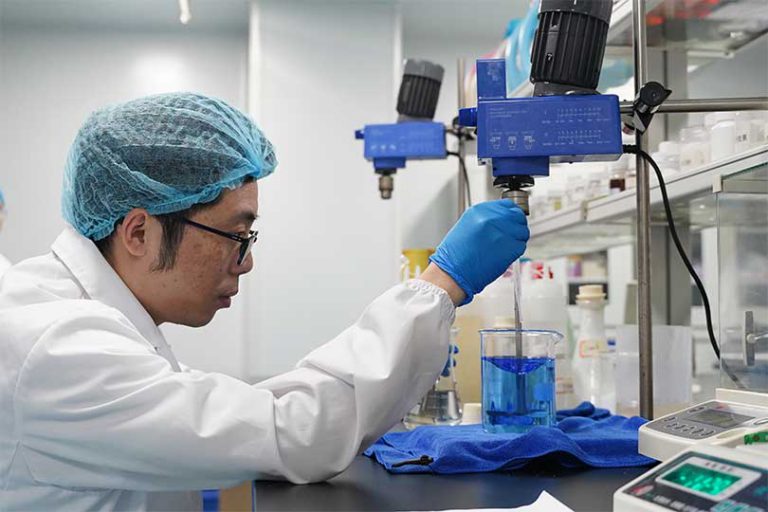

We firmly believe that a great product is both the crystallization of precise science and the embodiment of sensory art. The R&D center combines the meticulousness of chemists with the inspiration of perfumers in an ideal way.

Integrate the principles of green chemistry into the entire life cycle of product development, actively research and develop more environmentally friendly and biodegradable formulations, as well as packaging solutions that reduce the use of plastics.

We have a modern large-scale production base, equipped with industry-leading automated production lines and a rigorous supply chain management system. We are committed to providing customers with efficient, stable and flexible large-scale production services, ensuring the seamless connection of products from the laboratory to the market.

We have multiple fully automatic high-speed gel bead filling lines, with a daily production capacity of over several million beads.The maximum production speed of the production line can reach over 1000 gel beads being filled and sealed per minute, and the production efficiency is industry-leading.

Equipped with large stainless steel emulsification reactors (with capacities ranging from 2 tons to 10 tons), the annual emulsification capacity exceeds tens of thousands of tons.The high-speed filling lines cover various packaging materials, including various-sized bottles and bagged supplementary packages, with a daily filling volume of up to hundreds of thousands of bottles.

By adopting automated batching, granulation, coating and packaging systems, the annual production capacity can reach several thousand tons.It is capable of reliably fulfilling large-scale orders from national brands and international chain supermarkets.

Establish long-term strategic cooperation with top global and domestic raw material suppliers to ensure the quality, price and supply stability of core raw materials; Have large raw material storage and finished product storage facilities, and have deep cooperation with multiple logistics companies, which can arrange various transportation methods such as land transportation and sea transportation to ensure that products are delivered to the designated locations on time and safely.

Single-chamber design, simple and elegant, with long-lasting fragrance. It can be customized to create a unique flavor that is exclusive to your brand.

A single pods of essence combines the functions of cleaning, softening and leaving fragrance. It makes laundry effortless, retains fragrance for a long time, and protects the clothes.

Four-chamber laundry beads

Clean, smooth, color-preserving, fragrance-retaining, germ-removing and dust-mite-removing. The eight-times-concentrated laundry beads provide you with more comprehensive care.

Six-chamber laundry beads, each bead combines six functions. It offers high value for money and strong market vitality.

Process Description:

The customer defines the product’s positioning (e.g., laundry detergent pod function, laundry care product category, and household cleaning product application), market objectives, and technical specifications. Both parties agree on the minimum order quantity, packaging format (bottle/bag/refill), material standards, and delivery timeline. After signing the contract, the development phase begins.

Formula Development:

The customer provides basic requirements or commissions a laboratory to develop a new formula. After three rounds of adjustments (testing pH, viscosity, and active ingredient content), the formula is finalized.

Packaging Design:

The packaging manufacturer designs the bottle/label according to the requirements, provides 3D drawings and material specifications (e.g., PET bottle + PP pump head), and begins production upon customer approval.

Raw Material Procurement:

The supply chain department purchases certified raw materials (surfactants, fragrances, etc.) and provides traceability documentation.

Mass Production and Filling:

Production is conducted in a cleanroom, with a gel bead packaging accuracy controlled to ±0.1g and a liquid product filling tolerance of ≤±1%.

Logistics and Transportation: Shipment will be made as agreed in the contract.

After-Sales Guarantee:

We provide 12-36 month warranty tracking, respond to customer complaints within 24 hours, and provide free return shipping for bulk issues.